Is Your Container Ready?

Get In Contact With Us Today

Is Your Container Ready?

Get In Contact With Us Today

Top Factors Influencing the Cost of 20 Shipping Containers?

The cost of 20 shipping containers can vary significantly based on several key factors. Understanding these factors is crucial for anyone involved in logistics and transportation. Container costs often fluctuate due to market demand, supply chain issues, and geographical locations.

Shipping containers come in different sizes and types, each affecting overall pricing. For instance, a standard 20-foot container will generally have a lower cost than a specialized one. Additionally, factors such as condition, age, and the seller's pricing strategy play important roles in determining these costs.

Navigating the complexities of shipping container pricing can be challenging. Market trends change, and one must remain adaptable to avoid overspending. Assessing the cost of 20 shipping containers requires careful research and planning. Finding the right balance between quality and cost is often a process of trial and error.

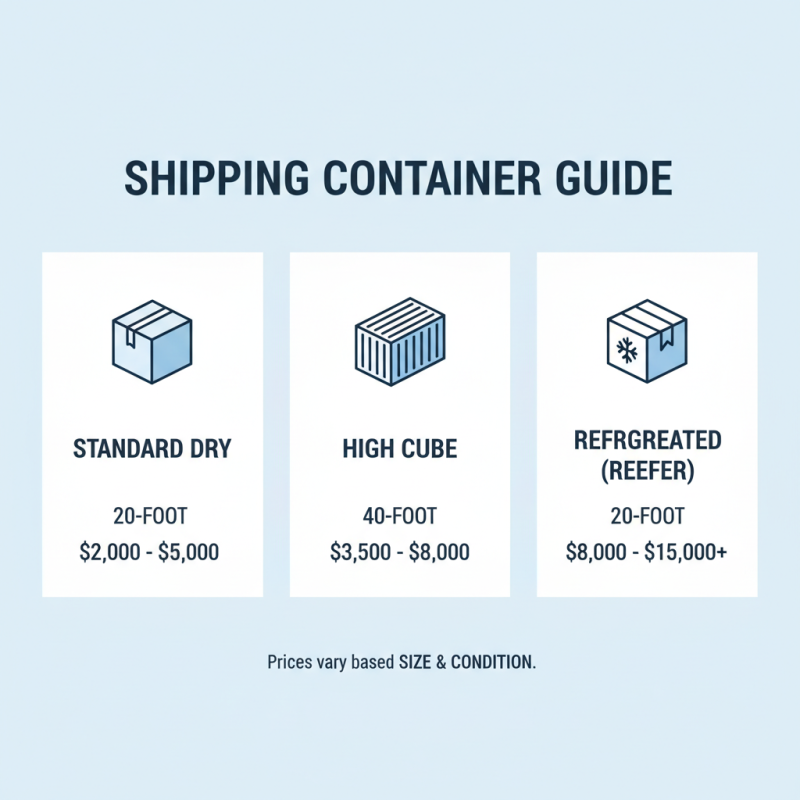

Major Shipping Container Types and Their Price Ranges

Shipping containers come in various types, and their prices can vary significantly. The most common types include standard containers, high cube containers, and refrigerated units. A 20-foot standard container typically ranges from $2,000 to $5,000. Gradually, the size and the condition of the container can greatly affect the price.

High cube containers offer extra vertical space, making them a popular choice for shipments requiring more volume. These containers usually cost between $3,000 and $6,000. Refrigerated containers, essential for transporting perishable goods, are pricier. Their prices can start around $4,500 and go up to $10,000. It's important to remember these figures can fluctuate based on market demand and location.

Quality matters too. A new container, while more expensive, provides better reliability. A used or distressed container may cost less but could bring unforeseen complications. Always assess the condition before purchase. Budgeting for potential repairs is wise to avoid overspending later. Choosing a container isn't merely about the initial cost; it's also about long-term value.

Influence of Container Condition on Shipping Costs

When considering shipping costs, the condition of a shipping container plays a vital role. A well-maintained container can save you money. Rust, dents, or leaks can significantly raise expenses. Damaged containers may incur extra handling fees. They often require more inspection and repairs, which adds to the total cost.

Conversely, new or refurbished containers tend to have higher initial costs. They are less likely to cause issues during transit. This reliability can justify their price. The choice of condition also impacts resale value. A container in excellent shape can command a better price later. However, buyers must weigh these aspects carefully.

Ultimately, owners face decisions regarding cost versus integrity. Choosing a cheaper, older container may lead to unforeseen expenses. Costs can spiral if the container needs repairs mid-journey. While it may seem like a good deal, it’s essential to reflect on long-term implications.

Top Factors Influencing the Cost of 20 Shipping Containers

This chart illustrates the average costs of 20 shipping containers based on their condition. New containers command the highest prices, while damaged ones are significantly cheaper. Understanding these price differentials is crucial for shipping companies and customers looking to optimize their logistics expenses.

Geographic Location and Its Impact on Shipping Container Pricing

Geographic location is crucial in the shipping container market. Ports near major trade routes often charge more due to high demand. According to a 2023 industry report, container prices can increase by 15% to 20% in busy regions like Los Angeles and Shanghai. This is driven by congestion and limited supply.

Distance also matters. If a shipping route covers longer distances, costs rise. For example, shipping from China to Europe can be up to 30% higher than within Asia. Transporting goods over vast oceans introduces fuel and time costs that cannot be ignored. This often leads to unexpected freight charges.

Political stability influences shipping costs too. Regions with unrest can see prices spike as supply chains become irregular. A rise in shipping fees by 25% has been observed in areas facing turmoil, affecting overall pricing. Shippers need to consider these risks, which can lead to lasting changes in costs. Each factor contributes to the intricate pricing of shipping containers globally.

Market Demand Trends Affecting Container Prices

The cost of shipping containers is highly influenced by market demand trends. According to industry reports, strong consumer demand can drive container prices significantly higher. For example, during peak seasons, prices for shipping containers can increase by over 30%. This spike often occurs as retailers stock up for holidays and sales events.

Additionally, recent data indicates that global trade volume plays a critical role in shaping container costs. In 2022, trade grew by 6.5% compared to the previous year, putting more pressure on availability. As demand rises, shipping companies often struggle to keep pace, leading to increased costs.

Capacity limitations can exacerbate this issue, making it harder for importers to secure necessary containers. Moreover, fluctuating fuel prices add another layer of complexity. When oil prices soar, operational costs rise. This inevitably passes down to consumers through higher shipping container prices.

The market’s volatility means that companies must continually reassess their strategies, often in reaction to sudden shifts in demand. Finding a balance remains challenging for many in the industry.

Additional Fees and Charges Associated with Shipping Containers

When shipping containers, various fees and charges can significantly impact the total cost. These additional expenses are often overlooked in initial calculations. For instance, terminal handling charges are common. They cover loading and unloading containers at ports. This can add up quickly, especially for multiple containers.

Another factor is documentation fees. These fees are charged for preparing shipping documents. Without proper documentation, shipments can be delayed. This adds stress and potential costs for businesses. Additionally, customs clearance fees may apply. Every international shipment must be cleared through customs, which incurs more charges.

Insurance is another key area to consider. Protecting the cargo can safeguard financial investments. However, it adds to the overall expense. Unexpected costs, such as storage fees, can also arise. Sometimes containers must sit at the port longer than planned. This happens due to paperwork issues or scheduling delays. These charges can be surprising and burdensome, making proper planning essential.

Related Posts

-

How Much Does It Cost to Buy 20 Shipping Containers in 2025?

-

Understanding LCL Container Shipping Benefits and Cost Savings for Your Business

-

Top 10 Benefits of Using ISO Containers for Shipping and Storage Solutions

-

What is a Cargo Container and How is it Used in Shipping?

-

How to Choose the Right Steel Container for Your Storage Needs

-

How to Choose the Best Refurbished Container for Your Needs