Is Your Container Ready?

Get In Contact With Us Today

Is Your Container Ready?

Get In Contact With Us Today

2025 Top Trends in Steel Container Usage and Innovation You Should Know

As we look towards the future, the steel container industry is poised for significant transformation and innovation. In 2025, we expect to witness a remarkable evolution in the usage of steel containers, driven by advancements in technology, sustainability initiatives, and changing market demands. Steel containers, known for their durability, versatility, and recyclability, are becoming increasingly crucial in various sectors, including logistics, construction, and packaging.

This overview will explore the top trends influencing the steel container landscape, highlighting the innovative practices that are reshaping the way we utilize these robust structures. From smart container technology that enhances tracking and security to eco-friendly initiatives that prioritize sustainability, the next few years promise to redefine the functionalities and applications of steel containers. The growing emphasis on environmental responsibility and efficiency will lead to the development of new materials and designs, making steel containers not only a practical choice but also a forward-thinking solution for businesses worldwide.

Through this exploration, we aim to shed light on the potential of steel containers to adapt to contemporary challenges and to showcase the innovative spirit driving their evolution, ensuring they remain integral to future industries.

Emerging Trends in Steel Container Design for 2025

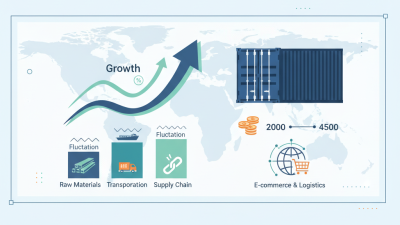

The steel container industry is witnessing significant innovations in design as it adapts to the evolving market demands and sustainability challenges of 2025. A recent report indicates that the global steel container market is projected to grow at a CAGR of 4.5% from 2022 to 2026, primarily driven by increasing requirements for durable and sustainable packaging solutions. This growth presents an array of emerging design trends that focus on enhancing functionality while reducing environmental impact.

One notable trend is the incorporation of eco-friendly coatings and finishes, which help extend the lifespan of steel containers and improve their recyclability. These innovations not only meet regulatory standards but also appeal to eco-conscious consumers. Additionally, modular designs are gaining traction, allowing for efficient stacking and transport, ultimately reducing the carbon footprint associated with logistics. A study from the International Steel Container Association highlights that modular containers can reduce transportation costs by up to 20%, showcasing their potential for industry-wide efficiency.

Tips for manufacturers include investing in advanced materials that improve the strength-to-weight ratio, thereby increasing the usability of containers without compromising structural integrity. Additionally, engaging in collaborative design processes with customers can foster innovation and lead to customized solutions that align with specific market needs. Emphasizing these trends in steel container design will not only enhance product offerings but also position companies as leaders in sustainability and innovation within the industry.

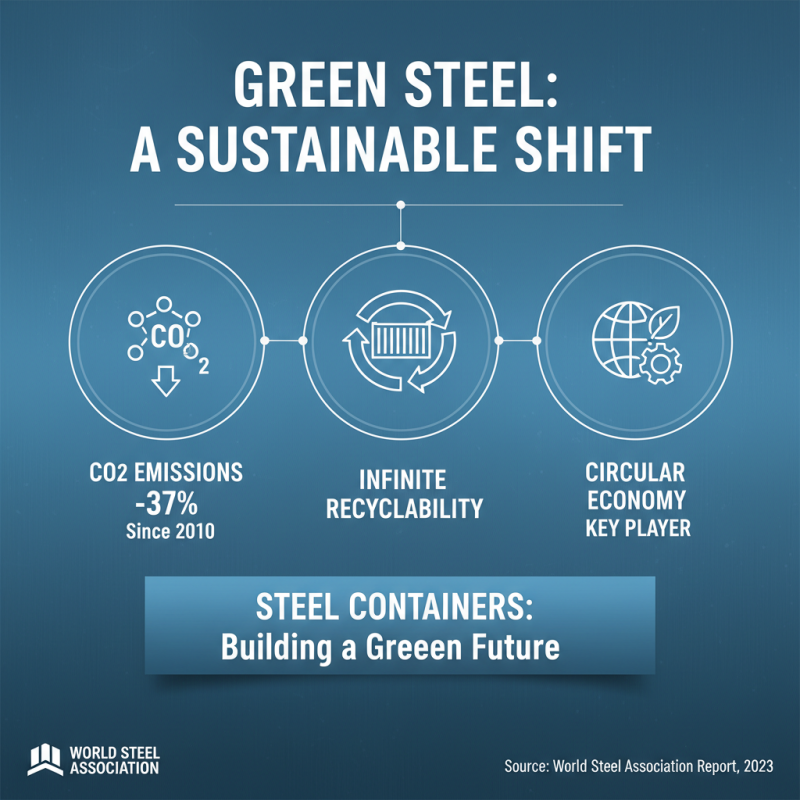

Sustainability Practices in Steel Container Production

The steel container industry is witnessing a significant shift towards sustainability practices, reflecting a broader trend across manufacturing sectors. According to a recent report by the World Steel Association, the steel industry's CO2 emissions have declined by 37% since 2010, thanks in large part to innovations in production processes and a push for recycling. Steel containers are gaining popularity because they can be recycled indefinitely without losing their structural integrity, making them a key player in the circular economy.

One notable trend is the implementation of energy-efficient technologies in the production of steel containers. Techniques such as electric arc furnace technology, which uses recycled scrap steel as raw material, reduce energy consumption significantly. A study published in the Journal of Cleaner Production highlights that steel production using arc furnaces emits approximately 75% less CO2 compared to traditional methods. As companies embrace these sustainable production methods, they not only lower their carbon footprint but also respond to consumer demands for environmentally responsible products.

Tips: To further enhance sustainability, companies should consider adopting practices such as optimizing their supply chains to reduce transportation emissions and implementing waste minimization techniques in their operations. By investing in R&D for stronger, lighter steel alloys, manufacturers can decrease the amount of material required for each container, thus conserving resources and lowering costs.

Technological Innovations Enhancing Steel Container Functionality

In recent years, the steel container industry has witnessed remarkable technological advancements that are reshaping both functionality and use cases. According to a report by Smithers Pira, the global market for steel containers is expected to grow at a compound annual growth rate (CAGR) of 4.2% from 2020 to 2025, driven largely by innovations in design and materials. One notable trend is the integration of smart technologies within steel containers, allowing companies to monitor their contents in real-time. These smart containers equipped with IoT (Internet of Things) capabilities enhance supply chain efficiency by enabling precise tracking, reducing waste, and optimizing inventory management.

Another significant innovation is the development of environmentally friendly coatings for steel containers, which enhances their durability and extends their life span. A report by the World Steel Association highlights that transitioning to water-based, low-VOC (volatile organic compound) coatings can significantly reduce the environmental impact of steel production. Furthermore, advancements in recyclable materials and the implementation of renewable energy in manufacturing processes underscore a broader commitment to sustainability. These innovations not only improve the functional aspects of steel containers but also align with global initiatives to reduce carbon footprints across industries, reflecting a growing emphasis on eco-friendly practices within the sector.

2025 Trends in Steel Container Usage and Innovation

This chart illustrates the anticipated impact of various innovation trends on steel container usage by 2025. The data shows that recyclability and durability are expected to have the highest influence on functionality, reflecting a strong move towards sustainable and robust container solutions.

Market Demands Shaping the Future of Steel Container Usage

The market demands for steel containers are evolving rapidly, driven by sustainability, efficiency, and innovation. As industries shift towards greener practices, steel containers are gaining recognition for their recyclability and durability. Businesses are increasingly seeking solutions that not only meet their logistical needs but also align with environmental standards. The future of steel container usage will likely feature designs that enhance energy efficiency and reduce carbon footprints, responding to both consumer expectations and regulatory pressures.

Tips for businesses looking to adapt to these trends include focusing on customization options that cater to specific industry needs. Tailoring steel containers with unique shapes or features can provide a competitive edge. Additionally, investing in technologies that improve the manufacturing process—such as automation and smart tracking systems—will streamline operations and increase service efficiency. Lastly, educating staff on the benefits of steel containers can foster a culture of sustainability within the organization, helping to drive the adoption of eco-friendly practices.

Moreover, as e-commerce continues to grow, the demand for versatile and sturdy packaging solutions becomes paramount. Incorporating innovations like modular designs or stackable features can greatly enhance space utilization during transportation. Companies should also consider collaborating with suppliers who focus on sustainable materials to ensure that their steel containers meet the highest environmental standards. Implementing these strategies will position businesses to thrive in the dynamic landscape of steel container usage.

2025 Top Trends in Steel Container Usage and Innovation You Should Know - Market Demands Shaping the Future of Steel Container Usage

| Trend | Description | Market Impact (%) | Projected Growth (2025) |

|---|---|---|---|

| Sustainability Initiatives | Increased demand for environmentally friendly containers made from recycled materials. | 35% | 1.5 million tons |

| Smart Containers | Integration of IoT technology for tracking and monitoring purposes. | 25% | 800,000 units |

| Custom Designs | Personalized steel container designs to meet specific client needs. | 20% | 500,000 units |

| Lightweight Materials | Adoption of advanced lightweight steel compositions for better efficiency. | 15% | 300,000 tons |

| Enhanced Safety Features | Implementation of advanced safety protocols and designs for risk reduction. | 5% | 200,000 containers |

Case Studies: Successful Implementation of Steel Containers in Various Industries

Steel containers have increasingly become a favored solution across various industries due to their durability and versatility. A notable case study can be observed in the agricultural sector, where farmers have successfully adopted steel containers for storage and transportation. According to a report by Steel Container Association, the utilization of steel containers can reduce product spoilage by up to 25%, significantly enhancing operational efficiency. In the food supply chain, for instance, using insulated steel containers has proven effective in maintaining optimal temperatures for perishable goods, thereby improving food safety standards.

Another compelling implementation is seen in the construction industry, where steel containers are repurposed for on-site storage and even as modular living spaces. Research indicates that using such containers can save up to 30% in costs compared to traditional building methods. Moreover, their durability allows for quicker project completion timelines without sacrificing quality. This innovative approach is being recognized globally, prompting more construction companies to explore the benefits of steel container usage as a sustainable option.

Related Posts

-

How to Choose the Right Steel Container for Your Storage Needs

-

Top 10 Benefits of Using ISO Containers for Shipping and Storage Solutions

-

What is a Secure Shipping Container and How Does It Work

-

How to Ship Goods via Container in 2025 for Maximum Efficiency and Cost Savings

-

How to Effectively Ship Goods via Container: A Complete Guide

-

How Much Does It Cost to Buy 20 Shipping Containers in 2025?